Downloads

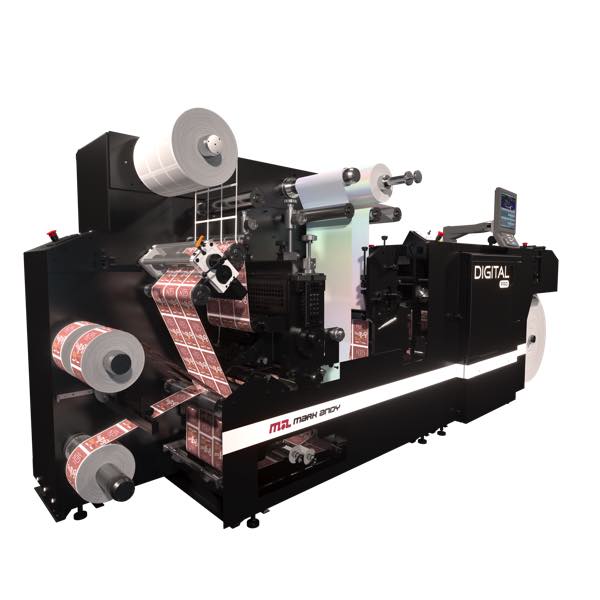

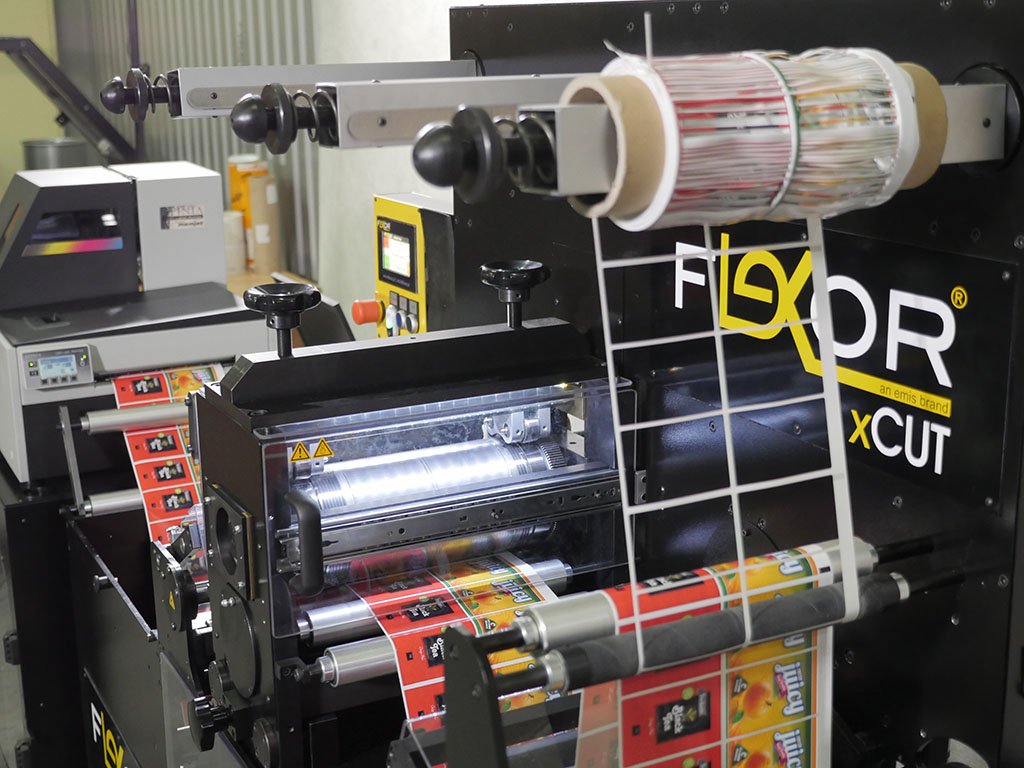

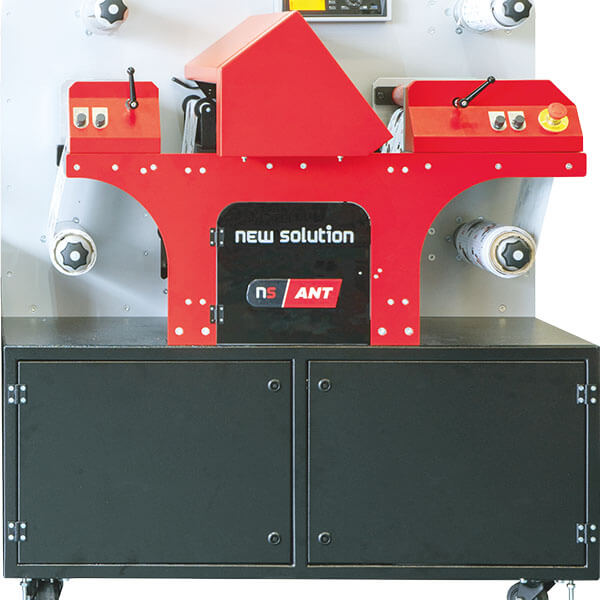

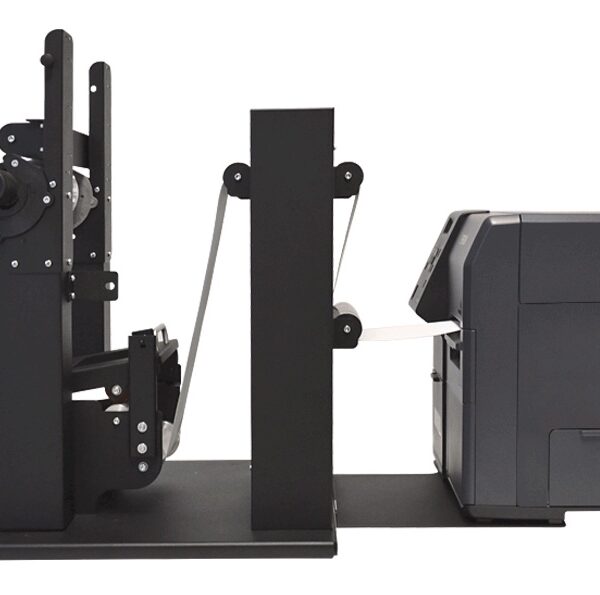

Semi rotary die cutting machine with option for digital printing – Flexor XCUT

| Max. speed ot semi rotary die cutting | 24 meters / min | 79 inches/ min |

| Max. speed ot full rotary die cutting | 30 meters / min | 98 inches/ min |

| Max. printing width (memjet) | 218 mm | 8.6 inches |

| Min. die cutting length | 152 mm | 6 inches |

| Max. die cutting length | 380 mm | 15 inches |

| Dimensions | 2700 х 920 х 1700 mm | 106 х 36 х 67 inches |

Flexor XCUT is ideal for customers who want to have a complete label producing process. With XCUT it is possible to print, laminate, die cut, slit longitudinally, separate the matrix and rewind the media with just one pass through the machine. Thanks to effective and affordable memjet technology, Flexor offers a machine that can work in a production line with a memjet printer.

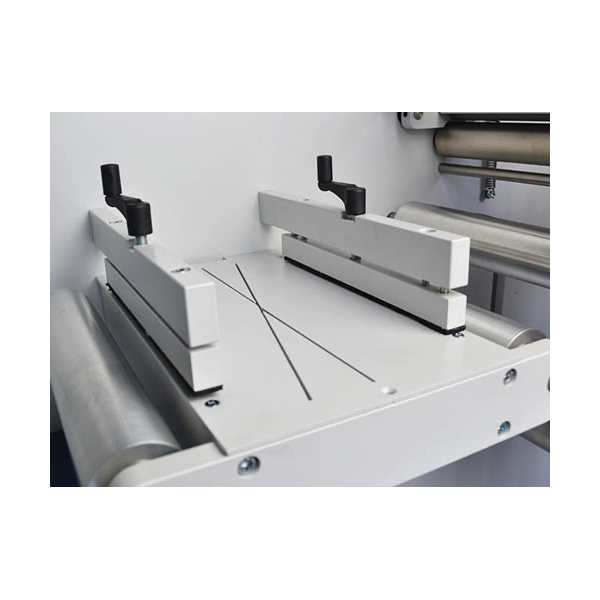

Semi rotary die cutting

- Speed up to 24 m / min

- Fixed, servo-driven 406 mm diameter magnetic cylinder

S-Drive machines deliver fast, cost-effective and super-fast production

- Automatic control of media tension

- Memory capacity – 36 jobs in queue

Video

Documents

Technical specification

| Max. speed ot semi rotary die cutting | 24 meters / min | 79 inches / min |

| Max. speed ot full rotary die cutting | 30 meters / min | 98 inches / min |

| Max. media guide width (Web) | 250 mm | 9.84 inches |

| Max. printing width (memjet) | 218 mm | 8.6 inches |

| Min. die cutting length | 152 mm | 6 inches |

| Max. die cutting length | 380 mm | 15 inches |

| Max media width for the unwider | 450 mm | 17.7 inches |

| Max media width for the unwider | 300 mm | 11.81 inches |

| Max. cutting width | 20 mm | 0.79 inches |

| Magnet cylinder dimensions | 406 mm / 128 teeth | 16 inches/ teeth |

| Black mark | 2х2 mm | 0.08х0.08 inches |

| Dimensions | 2700х920х1700 mm | 106х36х67 inches |

Flexor® is a brand of EMIS. Bradna specializes in the production of finishing machines and rewinding mechanisms.

Flexor® has become synonymous with quality, durability and ease of use. This is evidenced by the fact that Flexor® has over 350 installed machines around the world.

The company started as a family business in 1995 in Warsaw. Flexor® has built excellent partnerships with German manufacturers and thus achieved the perfect symbiosis between German quality and Polish craftsmanship.

The company maintains close relationships with its customers and builds long-lasting partnerships with them because it believes that this is the right path for development and innovation.

Related products

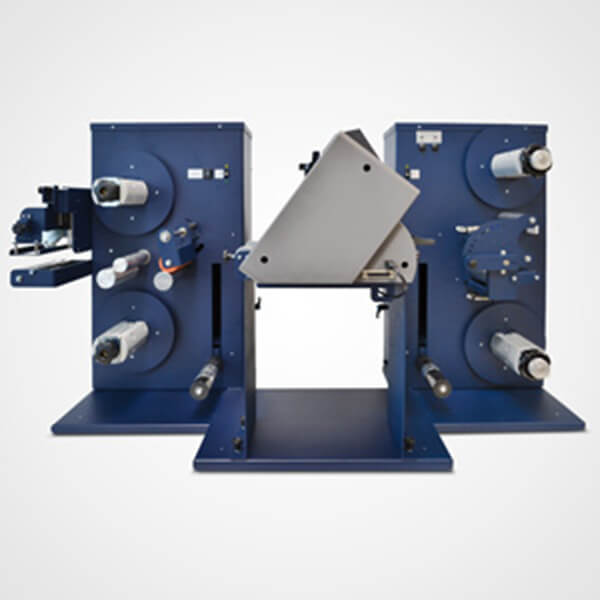

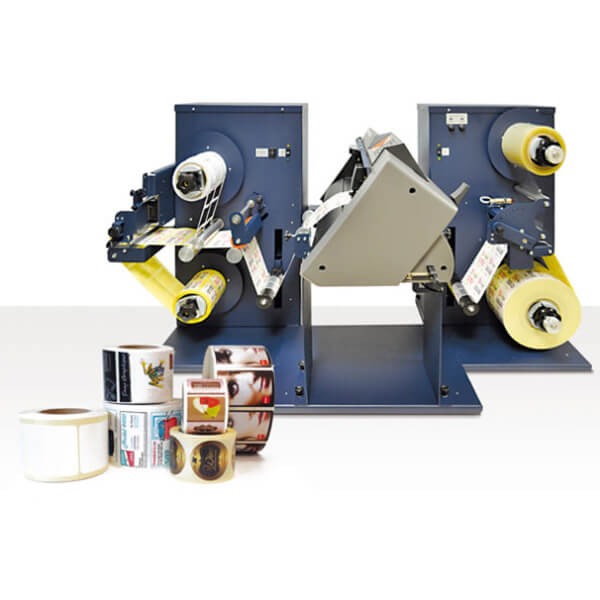

Digital finishing machine – Lemorau EBRM +

| Maximum rotary speed | 80 m/min. (262.4 ft/min.) |

| Maximum semi-rotary speed | 25 m/min (82 ft/min.) |

| Web width | 250, 330 mm (10, 13") |

| rewinder mechanical shaft | max. diameter 360mm (14") |

| waste rewinder mechanical shaft | max. diameter 450mm (18") |

| linerless lamination unwinder mechanical shaft | max. diameter 300mm (12") |

Reviews

There are no reviews yet.