Labels for cannabis and products containing cannabis

Digital printing, creativity, flexible packaging and sustainability have become the hallmarks of this evolving, thriving market.

Remember when the only way to acquire cannabis products was by buying on the black market? But seriously, in most places in North America, the days when cannabis users had to resort to black or gray market deals are long gone. When it comes to cannabis and cannabis packaging, the market is now green – the color of money.

The US cannabis packaging market was valued at $842.7 million in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 30.6% from 2022 to 2030, according to Grandview Research. The firm says the market is witnessing significant growth due to the increasing legalization of cannabis use in the US. To date, the recreational use of cannabis has been legalized in 21 US states, Guam, the Northern Mariana Islands and Washington, D.C., while numerous other states and US territories have decriminalized its use, perhaps paving the way for further legalization. Internationally, more dominoes continue to fall. In North America, Mexico and Canada have legalized cannabis nationwide. Many cannabis experts believe it is only a matter of time before cannabis is legalized at the federal level.

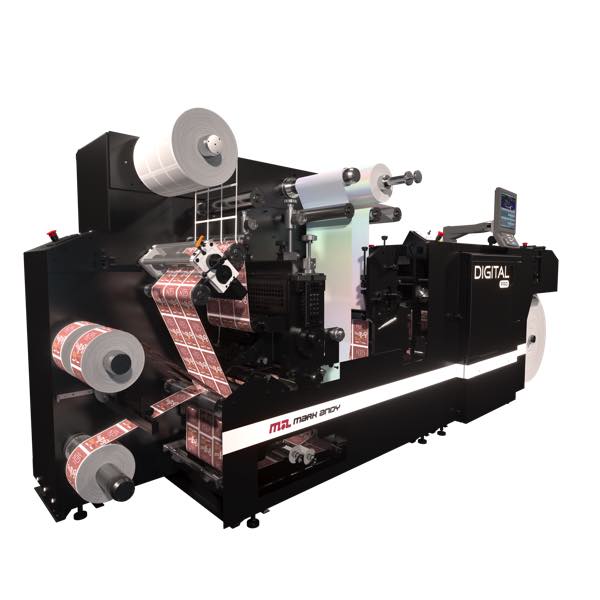

Katrina Edwards, new business and digital sales advisor, at Mark Andy, commented: “This has been a rapidly growing market segment and will continue to grow rapidly as more states legalize cannabis for medical and recreational use. And it’s no longer just cigarettes and food,” she says. “There are all kinds of products in foods, beverages, topicals, strips, etc. Cannabis and CBD have really branched out into all kinds of products that consumers can buy – and in all kinds of packaging.”

The types of packaging for cannabis products are many and varied. Outside of the print segment, demand is strong for glass and plastic jars and tubes in all shapes and sizes, and their accompanying caps, in addition to resealable and odor-resistant pouches. And in the printing and converting space, there is huge demand.

Sophistication and spread

Mark Andy‘s Edwards reiterates the need to be smart as a print and packaging supplier. “There are many different SKUs in the cannabis market for so many different manufacturers/brands entering the space. In addition, government regulations are constantly changing, requiring labeling and packaging to be modified to meet changing guidelines before they can be sold. Additionally, the need for variable data capabilities to display expiration dates and strain details is a must in the cannabis market.

“It’s not just labels that are used in cannabis packaging,” continues Edwards. “There are many different types of packaging, including childproofing elements, cardboard boxes with all kinds of foil effects and decorations, and so many unique, creative designs. Some users may find the luxury packaging more attractive, while others may be more interested in features like child protection. Some brands may want to have a more luxurious feel, while others may be more inclined to focus on a minimalist, organic, healthy, bold, modern and even sustainable packaging look.

Digital printing, of course

The multitude of SKUs, variable data, and frequently changing labeling requirements all point to digital printing technology being a huge boon to the cannabis industry.

Mark Andy‘s Edwards states: “This is a perfect industry to take advantage of digital printing. Cannabis labels require all kinds of variable information, including lot numbers, strain percentages, barcodes, and expiration dates. Usually, most of the brands making the products have smaller production capabilities and can only make smaller batches at a time, which is great for short runs. There’s also a shorter shelf life for the products, so making more at once – unless mass-produced – makes more sense to print on a digital press. If you have a mass production brand for large distribution, they could print on flexo, but they would still need to have a single variable data print (VDP) digital press, or they would probably need to run the VDP information on a smaller printer or as a separate label.’

Be flexible

As processors turn to digital printing technology as a means to stay nimble for their cannabis customers, the ability to produce flexible packaging is another area that benefits cannabis market profits.